All Products

-

Oil Drilling Tool

-

Downhole Power Tool

-

Oilfield Drilling Jars

-

Downhole Mud Motor

-

Downhole Drilling Motor

-

Oil Drill Bit

-

Tricone Drill Bit

-

PDC Drill Bit

-

Oilfield Fishing Tools

-

Foundation Drill Rig

-

Oil Extraction System

-

Solids Control System

-

Measure While Drilling

-

Tungsten Carbide Bearing

-

Oil Drilling Tools & Drilling Instruments Precision Machinery Manufacturing Services

MIJ Monolithic Insulating Joint In Pipeline

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Name | Insulation Joint | ||

|---|---|---|---|

| Highlight | MIJ Monolithic insulating joint,Monolithic Insulating Joint In Pipeline,MIJ Monolithic pipe insulation joint |

||

Product Description

Insulation Joint

Basic Info.

Model NO.

DN450PN10MPa

Cross-Section Shape

Round

Connection Type

Welding

Transport Package

Wooden Cases Free of Fumigation

Origin

Langfang China

HS Code

85479010

Production Capacity

10000

Product Description

Brief Product Introduction

Monolithic Insulating Joints (MIJ for short) are developed in cathodic protection to steel pipeline system which is used to replace the insulating flanges. MIJ is more convinient in field installation. What the user need to do is welding the MIJs to norminated pipeline and work with the cathodic protection system together to provide anti-corossion protection. The pipeline without cathodic protection is very easy to be corroded in 3 years. But the pipelines which are applied the cathodic protection will work as long as more than 30 years. So MIJs are more and more widely used in long didtance pipeline.

What we provide to customers is the first class quality monolithic insulating joints in China even in all over the world. The MIJs are manufactured by the famouse insulating joint manufacturer of China whose name is Langfang VBA Mechanical Co.,Ltd. Patented U-Sealing system is used in our MIJs which provides a more stable sealing performance compared to the O-Sealing System. The structure is designed as per ASME VIII DIV1 APP 2. Besides the standard products we also accept custom making order as per the specification and data book of customers.

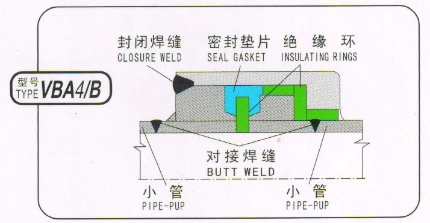

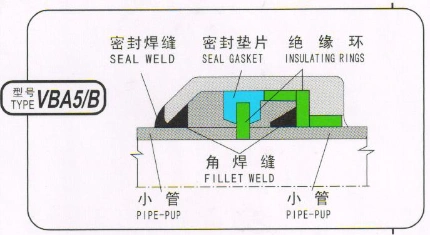

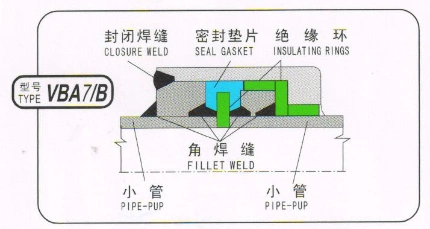

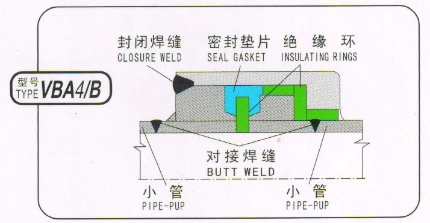

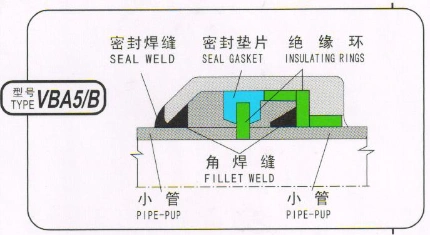

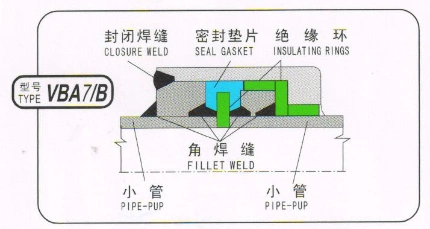

Usually there are three types of insulating joints available shown as below:

Standard Products Available

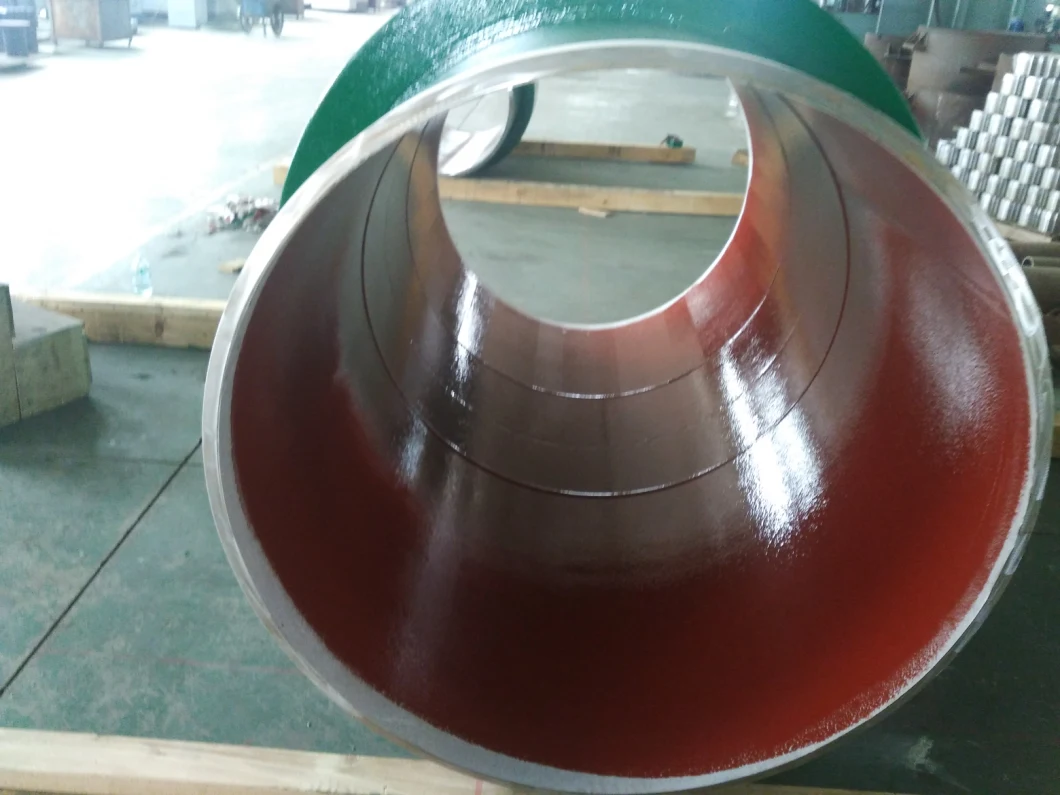

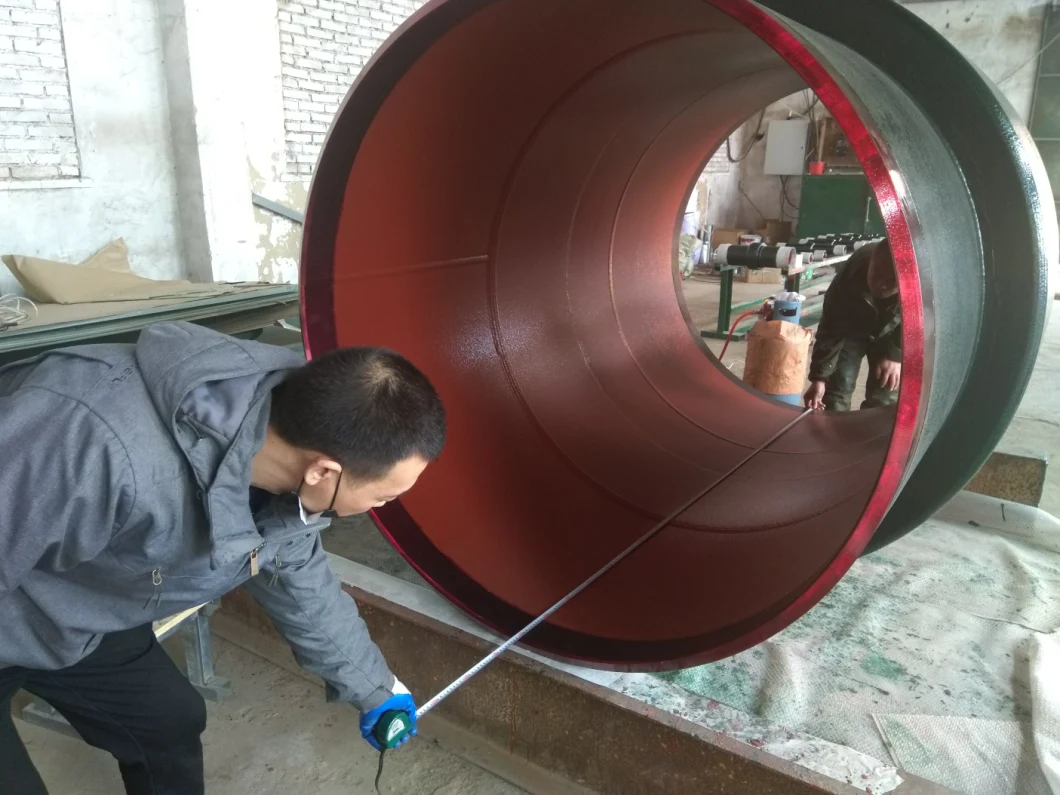

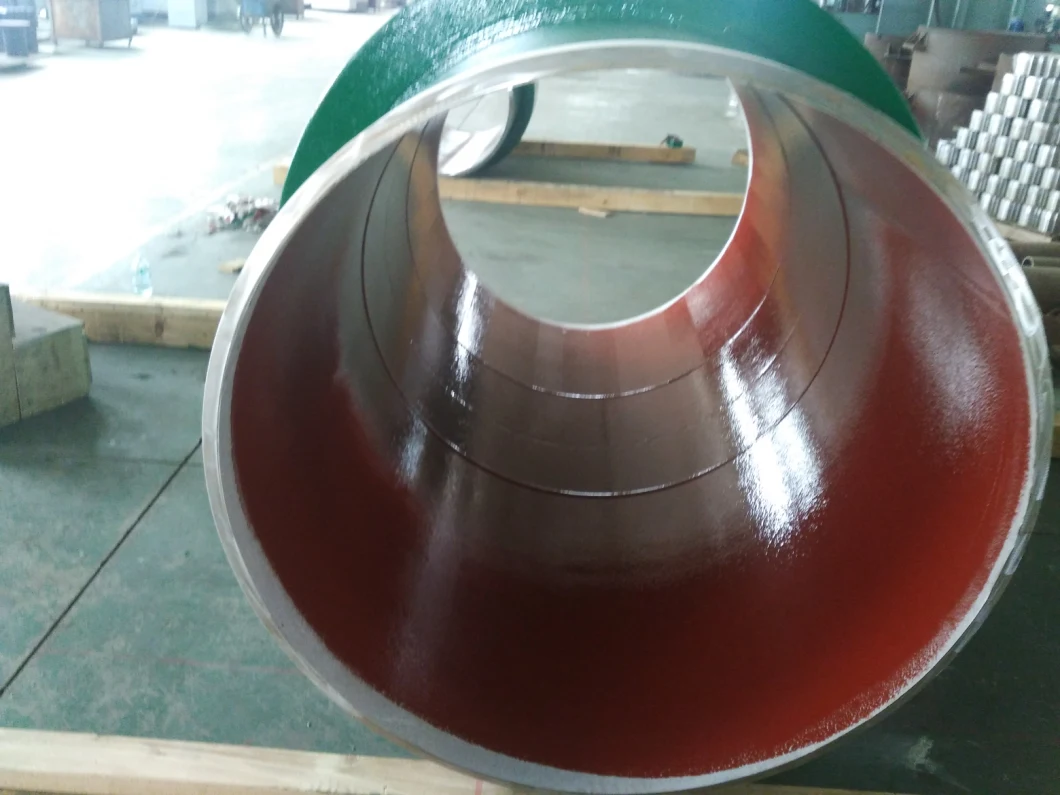

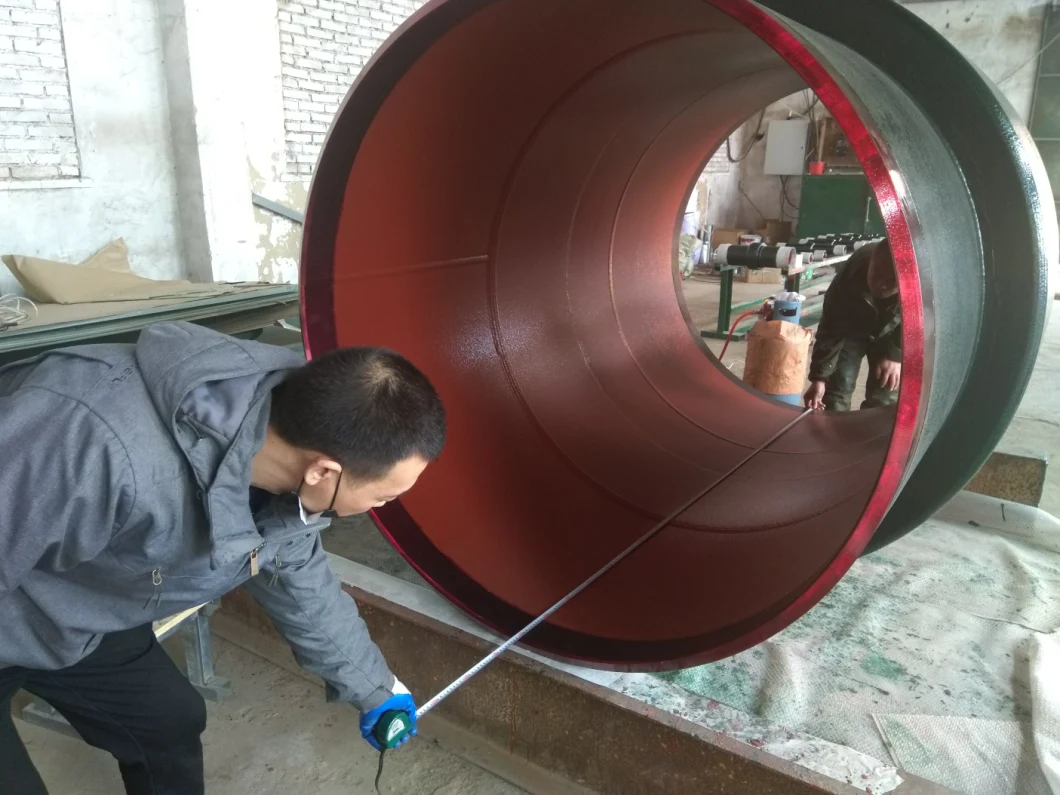

Monolithic Insulating Joints production Key Procedure

Flange Machining

Welding

Sand Blasting

Hydro Test

Painting

Film Adhesion Test

Holiday Test

Dry Film Thickness Test

Dimensional Check

Monolithic Insulating Joints (MIJ for short) are developed in cathodic protection to steel pipeline system which is used to replace the insulating flanges. MIJ is more convinient in field installation. What the user need to do is welding the MIJs to norminated pipeline and work with the cathodic protection system together to provide anti-corossion protection. The pipeline without cathodic protection is very easy to be corroded in 3 years. But the pipelines which are applied the cathodic protection will work as long as more than 30 years. So MIJs are more and more widely used in long didtance pipeline.

What we provide to customers is the first class quality monolithic insulating joints in China even in all over the world. The MIJs are manufactured by the famouse insulating joint manufacturer of China whose name is Langfang VBA Mechanical Co.,Ltd. Patented U-Sealing system is used in our MIJs which provides a more stable sealing performance compared to the O-Sealing System. The structure is designed as per ASME VIII DIV1 APP 2. Besides the standard products we also accept custom making order as per the specification and data book of customers.

Usually there are three types of insulating joints available shown as below:

Standard Products Available

| NO. | Size | De | Material | Class 600 | Weight | |||||

| In | mm | mm | S | L | B | Db | Type | KG | ||

| 1 | 1/2 | 15 | 21.3 | GrB/L245 | 3.7 | 250 | 98 | 83 | 5/B | 6 |

| 2 | 3/4 | 20 | 26.7 | GrB/L245 | 3.9 | 250 | 94 | 85 | 5/B | 6 |

| 3 | 1/2 | 25 | 33.4 | GrB/L245 | 3.9 | 250 | 100 | 88 | 5/B | 6 |

| 4 | 1-1/4 | 32 | 42.4 | GrB/L245 | 3.9 | 300 | 100 | 91 | 5/B | 9 |

| 5 | 1-1/2 | 40 | 48.3 | GrB/L245 | 3.9 | 300 | 100 | 94 | 5/B | 9 |

| 6 | 2 | 50 | 60.3 | GrB/L245 | 3.9 | 350 | 104 | 114 | 5/B | 10 |

| 7 | 2-1/2 | 65 | 76.1 | GrB/L245 | 5.5 | 350 | 117 | 132 | 5/B | 15 |

| 8 | 3 | 80 | 88.9 | GrB/L245 | 5.5 | 500 | 123 | 155 | 5/B | 23 |

| 9 | 4 | 100 | 114.3 | GrB/L245 | 6 | 500 | 128 | 190 | 5/B | 34 |

| 10 | 5 | 125 | 141.3 | GrB/L245 | 6.5 | 600 | 148 | 217 | 5/B | 53 |

| 11 | 6 | 150 | 168.3 | X52/L360 | 7.1 | 600 | 161 | 248 | 5/B | 74 |

| 12 | 8 | 200 | 219.1 | X52/L360 | 8.2 | 600 | 183 | 297 | 5/B | 118 |

| 13 | 10 | 250 | 273 | X52/L360 | 9.3 | 800 | 211 | 368 | 7/B | 212 |

| 14 | 12 | 300 | 323.8 | X52/L360 | 9.5 | 800 | 232 | 440 | 7/B | 317 |

| 15 | 14 | 350 | 355.6 | X52/L360 | 12.7 | 1000 | 231 | 455 | 7/B | 380 |

| 16 | 16 | 400 | 406.4 | X60/L415 | 12.7 | 1000 | 280 | 540 | 7/B | 592 |

| 17 | 18 | 450 | 457.2 | X60/L415 | 14.3 | 1000 | 290 | 600 | 7/B | 755 |

| 18 | 20 | 500 | 508 | X60/L415 | 15.9 | 1200 | 308 | 684 | 4/B | 1057 |

| 19 | 22 | 550 | 558.8 | X60/L415 | 17.5 | 1200 | 342 | 730 | 4/B | 1325 |

| 20 | 24 | 600 | 609.6 | X60/L415 | 19 | 1200 | 388 | 810 | 4/B | 1795 |

| 21 | 26 | 650 | 660.4 | X60/L415 | 19 | 1200 | 400 | 845 | 4/B | 2003 |

| 22 | 28 | 700 | 711.2 | X60/L415 | 19 | 1300 | 405 | 890 | 4/B | 2265 |

| 23 | 30 | 750 | 762 | X60/L415 | 19 | 1300 | 421 | 970 | 4/B | 2733 |

Monolithic Insulating Joints production Key Procedure

Flange Machining

Welding

Sand Blasting

Hydro Test

Painting

Film Adhesion Test

Holiday Test

Dry Film Thickness Test

Dimensional Check

Recommended Products