-

Oil Drilling Tool

-

Downhole Power Tool

-

Oilfield Drilling Jars

-

Downhole Mud Motor

-

Downhole Drilling Motor

-

Oil Drill Bit

-

Tricone Drill Bit

-

PDC Drill Bit

-

Oilfield Fishing Tools

-

Foundation Drill Rig

-

Oil Extraction System

-

Solids Control System

-

Measure While Drilling

-

Tungsten Carbide Bearing

-

Oil Drilling Tools & Drilling Instruments Precision Machinery Manufacturing Services

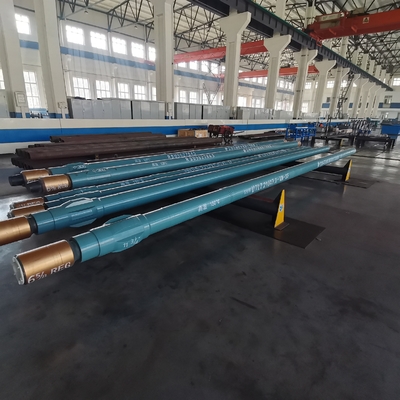

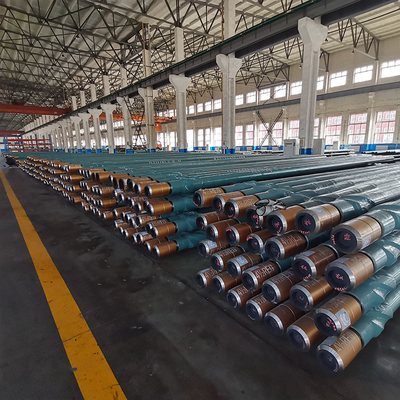

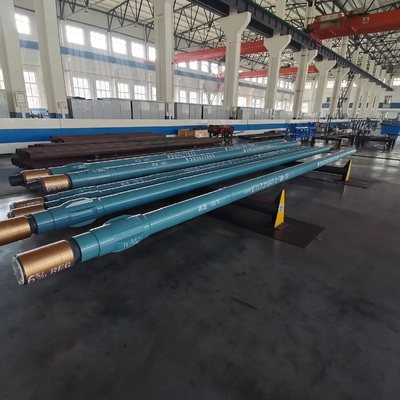

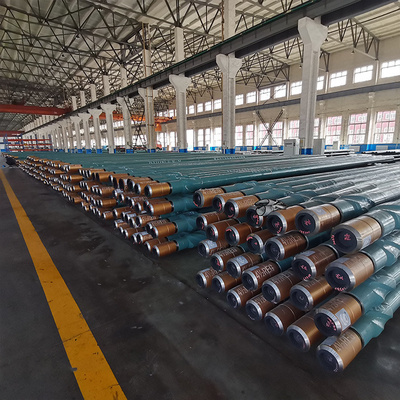

73-286mm Down Hole Motor Directional Drilling / Pdm Mud Motor

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Down Hole Motor Directional Drilling / Pdm Mud Motor | Keyword | Down Hole Motor Directional Drilling |

|---|---|---|---|

| Type | Pdm Mud Motor | Other Name | Positive Displacement Motor Drilling |

| High Light | 73mm down hole motor directional drilling,pdm down hole motor directional drilling,286mm pdm mud motor |

||

down hole motor directional drilling / pdm mud motor

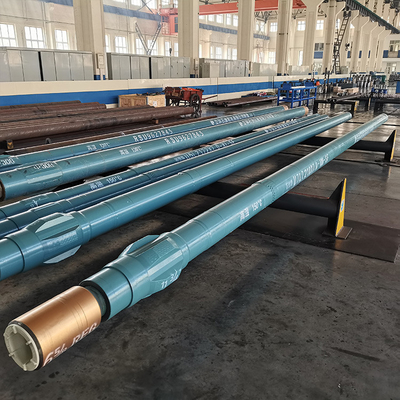

1. Adjustable bend

2. High temperature

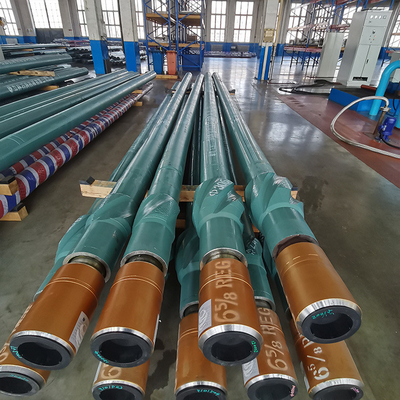

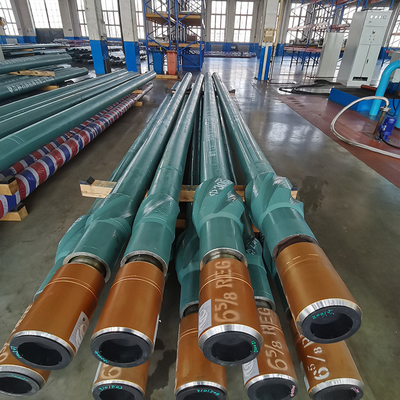

3. Tungsten carbide or Chrome coating rotor

A Downhole Motor, also known as a mud motor is a positive-displacement motors that is used during field drilling operations to provide rotational power to drill bits and other downhole tools.The unique feature about downhole motors is that they are powered by the drilling mud itself.The motor converts the hydraulic power of the fluid into mechanical power so as to rotate the bit.

Downhole motors provide rotational power to drill bits and other downhole tools.Such types of positive displacement motors have downhole turbine motors which are powered by drilling fluids.They are connected to the drill bits and allow the rotation of the drill bit and other downhole drilling equipment and tools without the need for rotating the drill strings located above the equipment.Such mud motors are extensively used in directional drilling, performance drilling, straight hole drilling, under reaming, milling and coring operations.

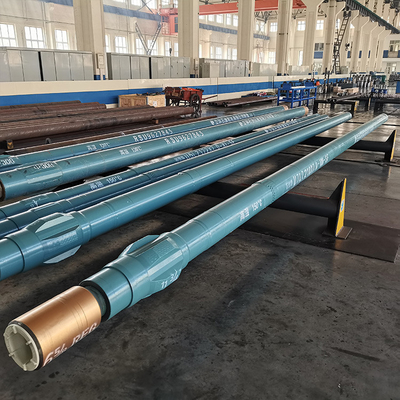

Downhole Motor Configuration Option

Even Wall downhole motor.

By change the internal shape of stator tube reasonably making the even wall power section.This kind of power section provides a shorter length, larger power, lower RPM, excellent heat disipation efficiency, larger application range, lighter weight etc.It performs great in super deep well, horizontal well and high temperature well drilling.

High temperature and OBM resistance downhole motor

This kind of downhole motor is usually used in high temperature, high oil content OBM.Special made rubber of stator works in the temperature as high as 180ºC and high oil content environment providing a good strength and tear resistance performance.Reasonable match of rotor and stator makes the high temperature rubber works well in high temperature and high oil content OBM environment.

Corrosion Resistance

Special corrosion resistance paint is made on the surface of rotors making the downhole motors works normally in corrosion environment.Usually Chrome Coated Rotors and TC Coated Rotors are available.